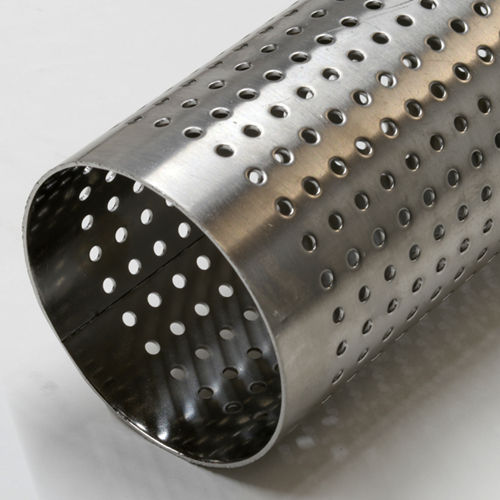

Stainless Steel Perforated Filter Tube: Precision-Filtering Solutions for Heavy-Duty Applications

The Stainless Steel Perforated Filter Tube is a high-strength, precision-engineered filtration component designed for heavy-duty industrial use. Constructed from 304/316 stainless steel, this tube features uniform perforations that ensure consistent flow rates, exceptional debris retention, and resistance to extreme pressures. Ideal for abrasive or high-viscosity media, it combines durability with adaptability for industries requiring reliable, long-lasting filtration.

Superior Material Quality

- Grades: 304, 316, or 316L stainless steel for unmatched corrosion and chemical resistance.

- High Pressure Tolerance: Withstands up to 50 MPa, ideal for hydraulic and pneumatic systems.

- Temperature Range: Stable performance from -50°C to 600°C (-58°F to 1112°F).

Customizable Design

- Hole Patterns: Round, square, or slotted perforations (0.5mm–10mm diameters).

- Open Area Ratio: 15%–60% to balance flow efficiency and particle retention.

- Dimensions: Custom outer diameters (10mm–500mm) and lengths (up to 6 meters).

Low Maintenance & Cost-Effective

- Easy to clean via backwashing or ultrasonic methods, reducing downtime.

- Reusable design minimizes replacement costs.

Advanced Manufacturing Process

Our perforated filter tubes are crafted using cutting-edge technology to ensure precision and reliability:

Material Preparation: High-quality stainless steel sheets or pipes are sourced from certified mills.

Laser/CNC Punching: Computer-controlled machines create precise, burr-free perforations for consistent flow paths.

Tube Forming: Flat perforated sheets are rolled and welded (TIG or seam welding) into cylindrical shapes.

Surface Treatment: Electro-polishing, passivation, or sandblasting to enhance corrosion resistance and aesthetics.

Quality Testing: Pressure tests, hole accuracy checks, and material composition verification (ISO 9001 certified).

Wide-Ranging Industrial Applications

Stainless steel perforated filter tubes are essential in:

- Oil & Gas: Sand control screens, wellhead filtration, and pipeline debris removal.

- Food & Beverage: Sieving grains, oils, and viscous liquids (FDA-compliant finishes).

- Wastewater Treatment: Filtering sludge, sediments, and industrial effluents.

- Mining & Construction: Separating aggregates and protecting machinery from abrasives.

- HVAC Systems: Airflow filtration in ducts and exhausts.

Why Partner With Us?

- ISO-Certified Production: Guaranteed consistency and compliance with global standards.

- Rapid Customization: Prototypes in 5 days, bulk orders in 3–4 weeks.

- 24/7 Technical Support: Expert guidance on design, installation, and maintenance.

Request a Free Sample today to test our perforated filter tubes in your application!