Sintered Mesh Filter Disc | Stainless Steel High-Pressure Filtration Solution

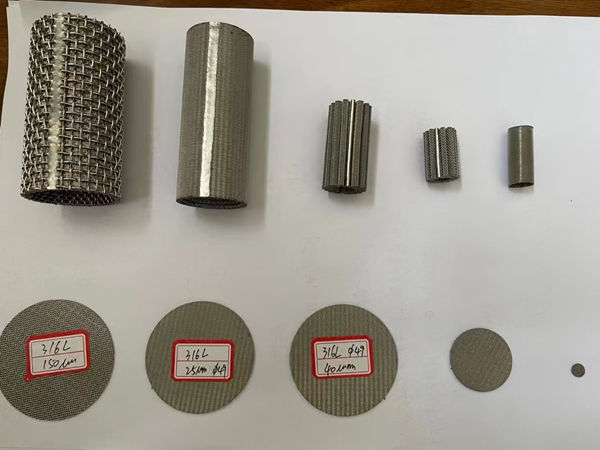

The Sintered Mesh Filter Disc is a high-performance porous filtration component crafted from premium stainless steel (grades 304, 316, or 316L). Utilizing advanced sintering technology, this filter disc delivers exceptional mechanical strength, corrosion resistance, and precise filtration capabilities. Ideal for harsh industrial environments, it ensures reliable separation of solids from liquids or gases while maintaining durability under extreme temperatures and pressures.

Performance Parameters:

Filtration Precision: 1–100 microns (customizable to meet specific requirements).

Porosity: 20–50% (optimized for high flow rates with minimal pressure drop).

Thickness: 1–10 mm (standard range; tailored designs available).

Operating Temperature: -200°C to +650°C (suitable for cryogenic to high-heat applications).

Maximum Pressure: Up to 30 MPa (dependent on thickness and porosity).

Material: 304, 316, or 316L stainless steel (excellent resistance to acids, alkalis, and organic solvents).

Manufacturing Process:

The sintered mesh filter disc is produced through a multi-step sintering process:

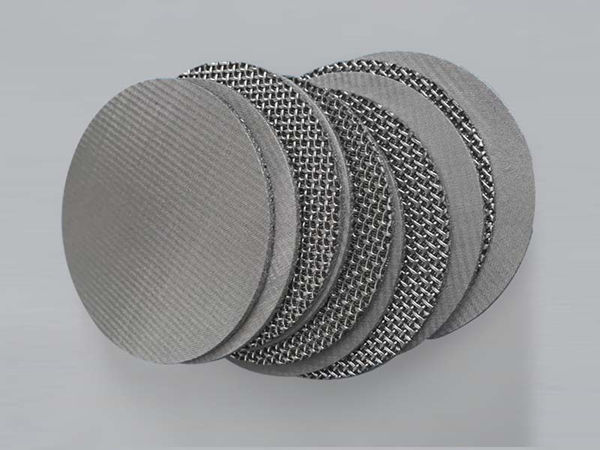

Layered Mesh Construction: Multiple layers of stainless steel wire mesh are stacked to achieve desired porosity and strength.

Cold Isostatic Pressing (CIP): Uniform pressure is applied to compact layers into a cohesive structure.

High-Temperature Sintering: The compacted mesh undergoes vacuum sintering at 1100–1300°C, fusing wires into a rigid, porous matrix.

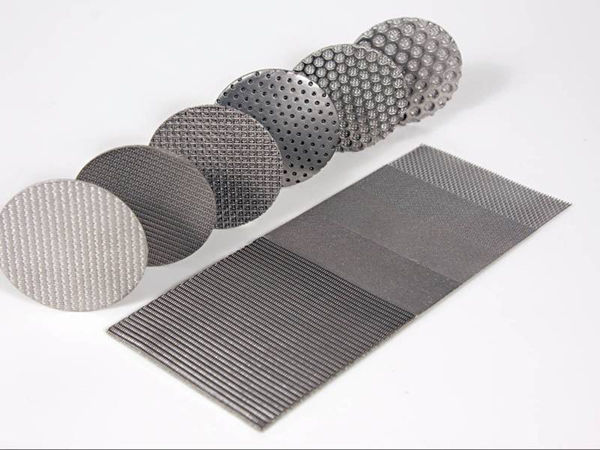

Post-Processing: Surface polishing, edge sealing, or laser-cutting ensures dimensional accuracy and leak-proof performance.

Advantages of Sintered Technology:

Stable Pore Structure: No pore deformation under high pressure or thermal stress.

High Dirt-Holding Capacity: Ideal for applications with heavy particulate loads.

Reusable & Cleanable: Backflushing, ultrasonic cleaning, or chemical rinsing restore functionality.

Applications:

1、Sintered mesh filter discs are widely used in industries requiring precision filtration and robustness:

2、Chemical & Petrochemical: Catalyst recovery, solvent filtration, and corrosive fluid processing.

3、Pharmaceutical: Sterile filtration of APIs, fermentation broth clarification.

4、Food & Beverage: Removal of impurities in edible oils, syrups, and brewing processes.

5、Water Treatment: Pre-filtration for reverse osmosis (RO) systems and wastewater purification.

6、Oil & Gas: Sand control in wellheads, hydraulic fluid filtration.

7、Automotive: Fuel injection systems and compressed air filtration.

Why Choose Our Sintered Mesh Filter Disc?

1、Customizable Design: Tailored dimensions, shapes, and porosity to match your system.

2、Long Service Life: Resists clogging, abrasion, and chemical degradation.

3、Certified Quality: Compliant with ISO 9001, ASME, and PED standards.

4、Cost-Effective: Reduced downtime and maintenance costs compared to disposable filters.